RoamIO

Korechi Innovation Inc seeks to make agricultural robots and automation as simple and accessible as possible. RoamIO is their first robot and the focus of their current development and marketing efforts.

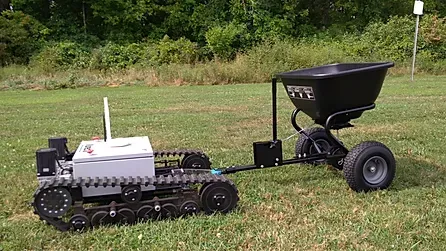

An autonomous agricultural robot with a smaller footprint

We previously profiled DOT, a large autonomous robot designed to replace a tractor. Let’s follow that up with a look at a similar autonomous robot, also developed in Canada, but instead of replacing a tractor, RoamIO is much smaller and more agile.

It’s designed to take over some of the monotonous or repetitive tasks on a farm, without compacting the soil or requiring significant capital.

Initially developed at McMaster University’s Innovation Park, RoamIO was also made possible by a $94,000 grant from the Canadian federal government via NSERC, the Natural Sciences and Engineering Research Council of Canada. Developed by Korechi Innovations Inc., RoamIO is a product of collaboration between the public and private sector, in concert with post-secondary institutions, including Niagara College and Durham College in addition to McMaster.

MIP-based Korechi Innovations Inc, a @forgemcmaster start-up, made their first sale - and made the news! They are now supplying the RoamIO autonomous robotic platform to @niagaracollege_ #Agriculture & Environmental Tech. Innovation Centre. Full story: https://t.co/M3qNMRgOE3

— McMaster Innovation Park (@MIP_Hamilton) November 14, 2018

Korechi creates robots that automate agricultural tasks, and their place at @forgemcmaster helped them reach customers and make their first sale. Learn about their RoamIO robot (and watch it tow an SUV!) in this video from our 'Best of The Forge' series https://t.co/2h9g85WUMF

— McMaster Innovation Park (@MIP_Hamilton) November 29, 2018

Founded in 2016 by Sougata Pahari, Korechi is now based in Oshawa, and affiliated with the Spark Centre and the AI Hub at Durham College.

An article about how Korechi came to be:https://t.co/DtXuxdtVvehttps://t.co/CTwhXcbkfo

— Sougata Pahari (@SGTPahari) July 4, 2019

with @forgemcmaster , @spark_centre and @KorechiInnov #Korechi #RoamIO pic.twitter.com/Oaa0KnY152

The company seeks to make agricultural robots and automation as simple and accessible as possible. RoamIO is their first robot and the focus of their current development and marketing efforts.

While the robot itself is relatively lightweight at 120kg, it can carry as much as 450kg, and tow as much as 2,200kg, making it a fairly powerful small size agricultural machine.

Like most autonomous vehicles it combines GPS with LIDAR (laser based radar) so that it can navigate a field, golf course, or vineyard.

An obvious application of RoamIO is to do seeding, as it can have a route pre-programmed, and an attachment that spreads the seed across the field. This would be far smaller than a tractor (resulting in less soil compaction) and easier than doing it manually.

Another application for RoamIO is turf or lawn maintenance, especially on a golf course, where the size of land is large, but not necessarily the complexity of the task. The robot could pull a lawn more or a golf ball retriever.

@KorechiInnov Roamio out on the range @AngusGlenGC today. Locally designed, engineered and built @cognashene pic.twitter.com/fHW3oBx2Wh

— Kevin Hennigar 🧰🔧⛳🇨🇦 (@Canadianeh79) October 23, 2019

RoamIO has a growing list of supported attachments that range from those used for turf care, to sprayers and seeders for agriculture.

It features sensors that enable collision avoidance and is relatively weather proof, although that may require further testing and evidence.

The device itself is controlled via software that allows an operator to upload their field information, select the area to cover, including desired path and exclusion zones, and then let the robot go and do it’s work.

A single charge of the default battery can last 8 hours, but can be extended further with different modifications.

As a robot, it could operate all the time, providing it can recharge, and could certainly operate at night in the dark, with comparatively low noise output.

With a current price tag of roughly $40,000 per unit, RoamIO is not cheap, unless you compare it to agricultural equipment and technology in general, in which case it is ironically not expensive. Similarly if there are enough tasks for this robot to perform, it could be cheaper than hiring someone, especially in the context of a golf course.

Although I do wonder about winter applications, and whether there will be ways it can be used year round. It doesn’t have a PTO attachment to operate a snow blower, but maybe it could be outfitted with a snow plow?!

At Niagara College, RoamIO was transformed into a kind of robot sentry, monitoring the vineyard, gathering data about the soil and crops, and using all of that to help manage, maintain, and inform the larger operations. This kind of open field surveillance may be more effective than having sensors installed, as the one robot can traverse the field fairly easily, and potentially cover more ground at a lower overall cost.

Similarly ground based surveillance offers advantages and capabilities that differ from drones and flying robots.

Meet "Korechi Roamio" a robot being built at @niagaracollege to assist with Ontario grape production. https://t.co/EOjDTmTVAe #ontag pic.twitter.com/te44h69Abo

— Farmtario (@farmtario) February 26, 2019

Artificial intelligence can measure much more than what the human eye can detect and robots’ abilities to work around the clock brings features to the agriculture industry that humans can’t physically complete.

Drones are difficult to use for this sort of work because they fly above the canopy, says Duncan. He wants to create a robot that works from the ground to identify factors within and under the canopy.

Although working on the ground brings better identification strategies and capabilities, it creates more challenges with manoeuvering the device around the surroundings and topography.

When working on the ground there is more of a chance for the robot to run into a tree or a pond and it’s a hard problem to solve, says Duncan.

The team, working with the original robot created and sold by Korechi, started off with attaching a camera and some temperature probes to a radio controlled car but had issues with having to continuously follow the car to control it and they wanted the device to be completely automatic. They needed something with weight and the ability to plow through thick grass, navigate itself and have enough charge to run 24 hours a day.

This is a great example of why collaboration with Universities and Colleges helps a company like Korechi further develop their technology and capabilities.

The agricultural industry also currently faces the dual problems of labour scarcity and aging demographics. Automated tools have an important role to play, both in performing menial tasks that humans don’t want to do, while also making it possible for older farmers to maintain their operations.

Robot automates hard-to-fill jobs in #agriculture and turf. #technology https://t.co/q6vWAjuxqI pic.twitter.com/UW0OmmXr9A

— Farmtario (@farmtario) January 14, 2020

Data collection for the SoilOptix soil sensing system is one application where RoamIO can autonomously move across even fields with heavy corn stubble. According to SoilOptix founder and CEO Paul Raymer, the unit is an ideal fit for how agriculture can reduce its dependence on human workers in the field.

“What we foresee is the swarm where maybe one field robot manager is managing two or three vehicles out of a single tablet,” he says. “When we incorporate robotics into the field, it adds one more level of control — this is the new frontier that is quickly starting to appear more and more.”

Kind of raises the question as to whether we’ll see the use of exo-skeletons in agriculture as a hybrid form of automation, humans, and machines.

RoamIO is still in its relatively infancy, but does provide an interesting example of how automation in agriculture as considerable potential. We’ll keep an eye on this device and the company that produces it, and will provide further updates as it advances.